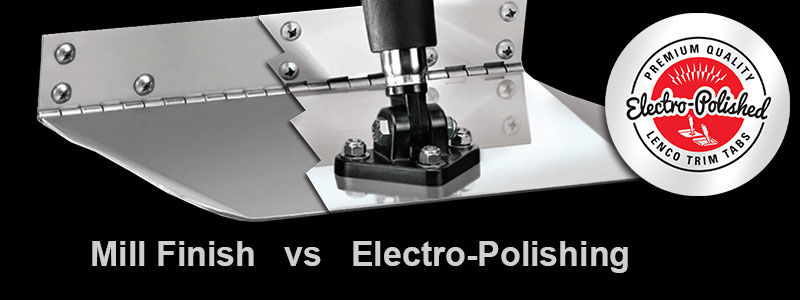

Electro-Polishing is a process that improves the surface finish of our 304 stainless steel trim tab blades. Electro-Polishing delivers a smoother, more reflective surface than our standard mill finish and improves surface cleanability.

Electro-Polishing dissolves free iron, inclusions, and embedded particles from the surface of our trim tabs.

Lenco’s in-house process improves the near-surface chemistry of the material, and promotes the formation of an improved corrosion resistant surface layer.

|

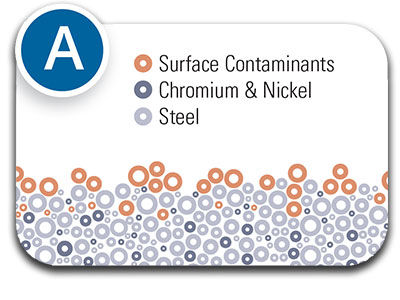

The raw form of all stainless steel has a mixture of unwanted surface contaminants such as iron and much needed elements such as chromium & nickel. |

|

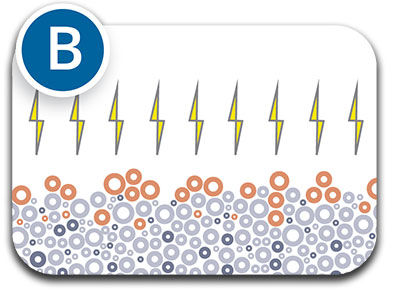

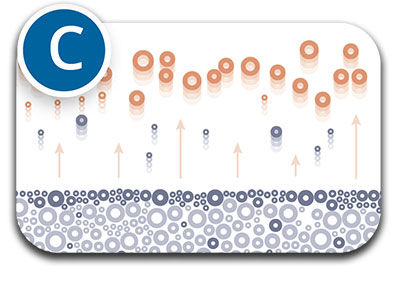

An electrical charge is added in order to remove unwanted surface contaminants and concentrate the chromium & nickel at the surface. |

|

What is left is a stainless steel that has become much more impervious to the environment with an aesthetically pleasing “BLING” appeal. |